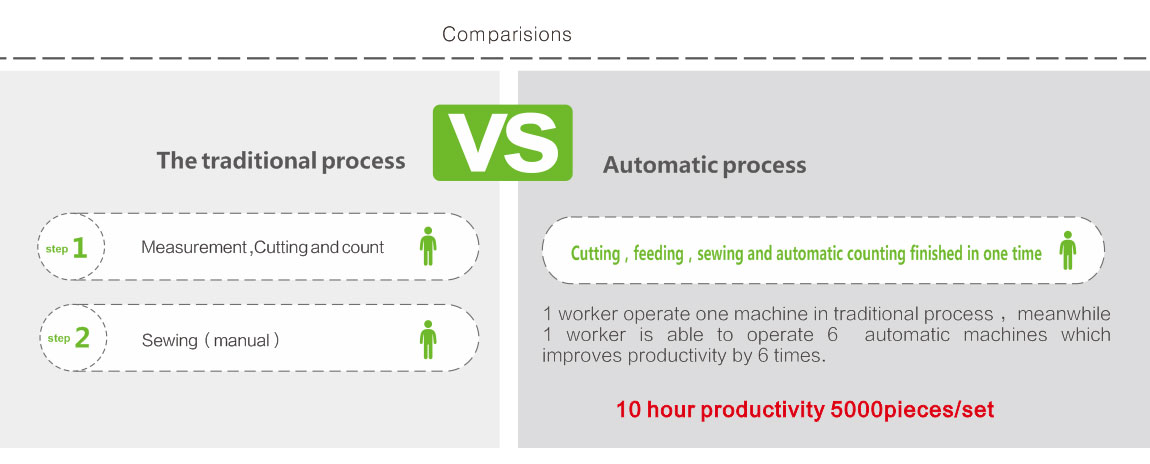

Product Introduction

SP-1007XJ-09/10/11LQ

Automatic Elastic Ribbon Splicing Machine

- SP-1007XJ-09LQ

- SP-1007XJ-10LQ

- SP-1007XJ-11LQ

Application

Apply to multiple specification rubber jointing, sewing lines smooth and beautiful.

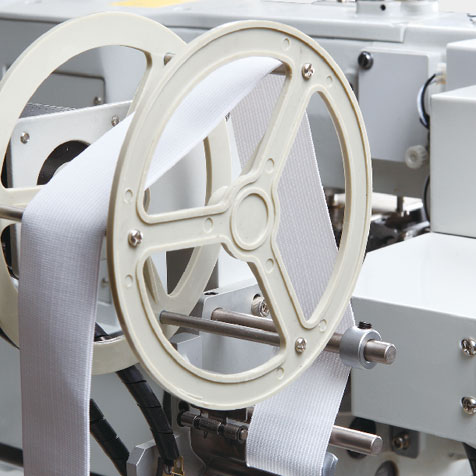

Receipt device

Rotary working plate receives material incessantly .Every bar receives materials around 200pieces ,total 600 pieces one time.

Ways of stitching

- The machine has two ways of stitching, namely overlapping and flat join.

- SP-1007XJ series: the diameter scope after the elastic jointed is 200-999mm and the width scope is 15-65mm

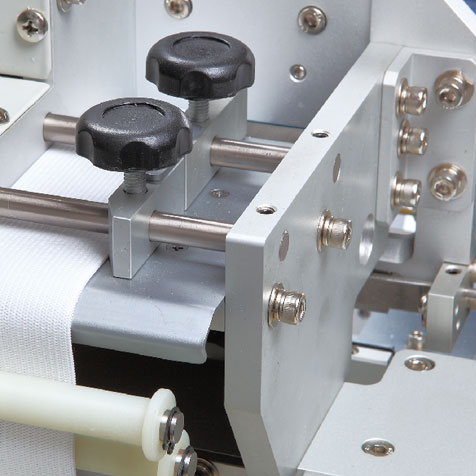

It is more convenient to adjust the size

Special tightening wheel of screws lowers the difficulty of adjusting the size of elastic ribbon .

Automatic stop for lack of material

The machine will stop automatically once the elastic ribbon has a joint or is depleted during continuous cycle sewing.

Automatic stop for lack of material

It adopts the rotary pulling device and motor to feed the elastic which guarantees the length trimming tolerance in 2mm.

Color mark recognition system

Introducing advanced Panasonic color mark recognition system for double colors elastic stitching, recognizing the position of the LOGO precisely, to ensure the LOGO in the center position against the jointing line, can stitch one big and one small length of elastic in each cycle, very efficiently save the wastage of elastic.It is a milestone to introduce the visual identification system in the sewing industry.

SP-1007XJ-10RQ/LQ (Graphic visual identification system)

Graphic visual identification system: the machine introduces advanced technology of Keyence sensor ,which ensures the absolute middle position between logo and Splicing place by accurately identifying LOGO position. The machine reduces the quantity of waste efficiently ,as it is able to sew one big size and one small size of elastic ribbon simultaneously.

SP-1007XJ-11RQ/LQ

Reduce the working proceure of manual point to point labeling so that can improve the efficiency.

Optional:Ironing device

After the elastic is ironed through the ironing device, it would be flat and beautiful, can prevent from shrinking, reducing the wastage, raising the production efficiency and sewing quality

-

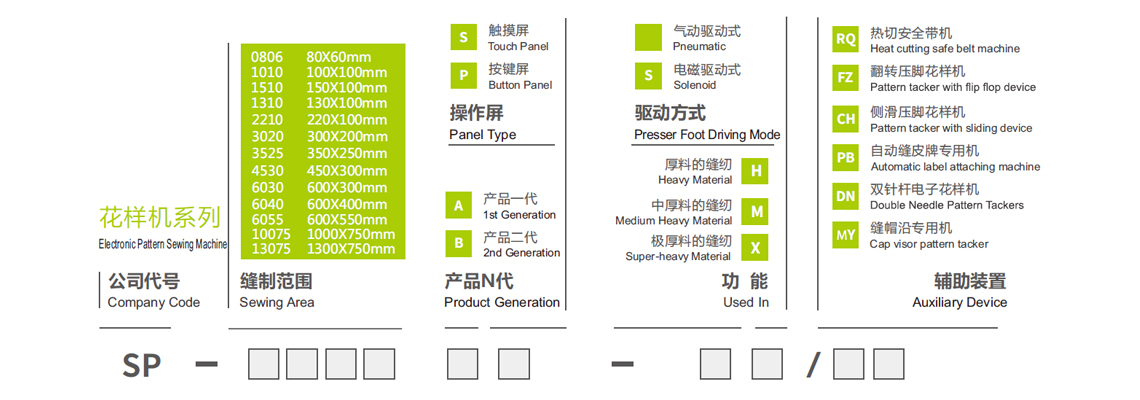

Model

Device

Line

Highest sewing speed

Sewing area

Cloth feeding mode

Stitch Length

Maximum stitch amount

Stitch No. can be stored

Presser foot driving method

Work clamp height

Rising amount of intermittent foot presser

Stroke by intermittent presser foot

Customer program amount

Recyle programme No.

Motor

Power

Air pressure

-

SP-1007XJ-09LQSing-needle flat seam2,800 rpm15×65mmIntermittent feeding(Pulse motor drive mode)0.05-12.7mm20,000 needles/1 pattern500000 stitch can be stored in build-inmomeryPulse motor driveMax.25mm22mm0 or 2-10mm(Factory defaults:3mm)509AC servomotor 550WSingle phase100~120V、200~240V、3-phase200~240V、380~415V、350V0.5Mpa、1.8L/min

-

SP-1007XJ-10LQGraphic visual identification systemSing-needle flat seam2,800 rpm15×65mmIntermittent feeding(Pulse motor drive mode)0.05-12.7mm20,000 needles/1 pattern500000 stitch can be stored in build-inmomeryPulse motor driveMax.25mm22mm0 or 2-10mm(Factory defaults:3mm)509AC servomotor 550WSingle phase100~120V、200~240V、3-phase200~240V、380~415V、350V0.5Mpa、1.8L/min

-

SP-1007XJ-11LQSpot Recognition systemSing-needle flat seam2,800 rpm15×65mmIntermittent feeding(Pulse motor drive mode)0.05-12.7mm20,000 needles/1 pattern500000 stitch can be stored in build-inmomeryPulse motor driveMax.25mm22mm0 or 2-10mm(Factory defaults:3mm)509AC servomotor 550WSingle phase100~120V、200~240V、3-phase200~240V、380~415V、350V0.5Mpa、1.8L/min

Download