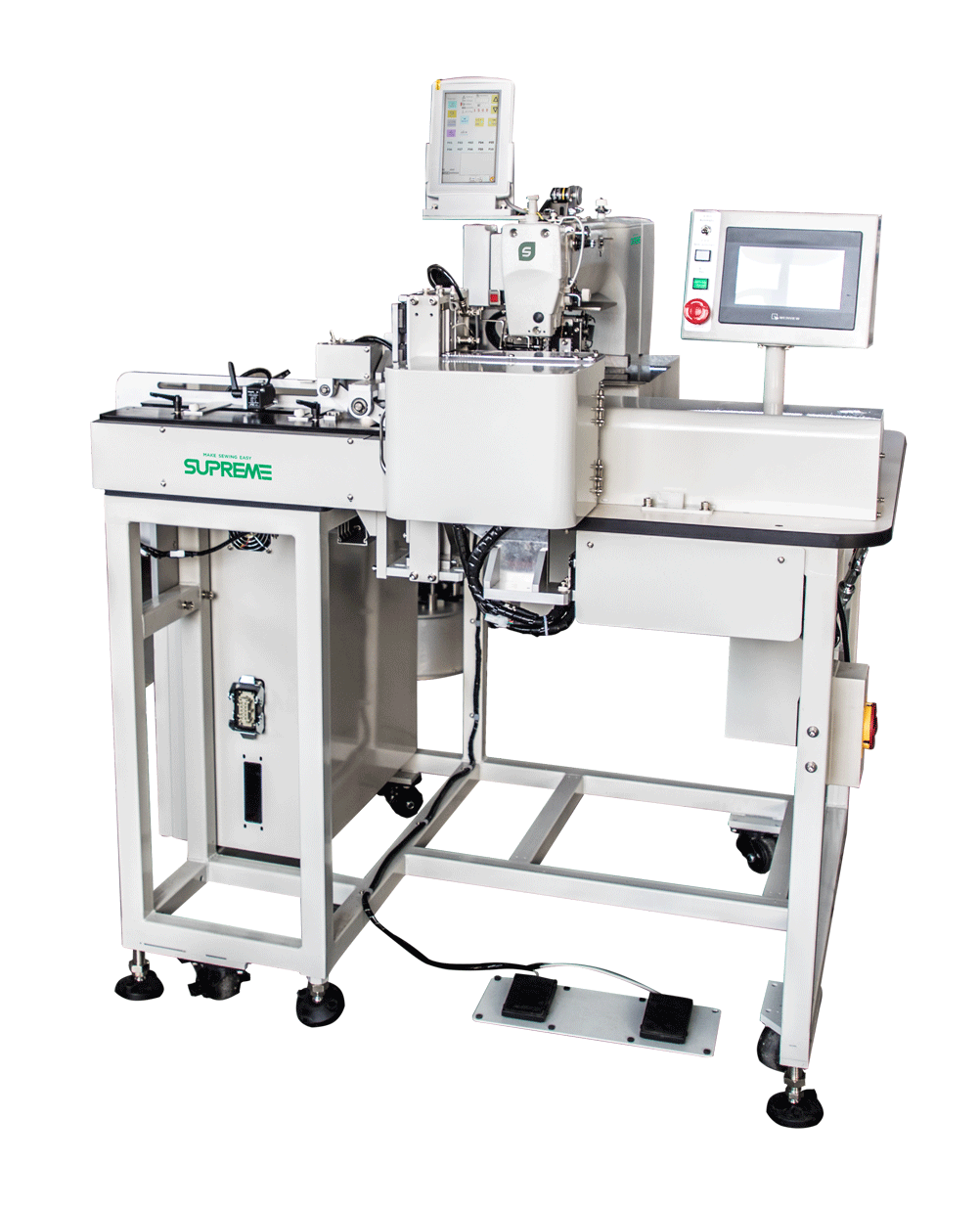

Product Introduction

SP-F161

Automatic Elastic Stitching Machine

- SP-F1610A

- SP-F1611A

- SP-F1612A

- SP-F1613A

- SP-F1614A

- SP-F1615A

Advantages

- It is convenient to adjust the size, and the design of the special locking and adjusting nut can greatly reduce the difficulty of adjusting the size of the rubber band.

- The machine will stop working immediately when the rubber band has a joint or the rubber band is used up during the continuous loop sewing process.

Advantages

- Introduce the advanced Panasonic color mark recognition system, aiming at the sewing of twocolor rubber bands. (Multi-color or similar two-color elastic stitching can be equipped with a visual recognition system), which can accurately identify the position of the LOGO and ensure the accurate half-folding of the LOGO and the elastic stitching. Each time you can sew two sizes, one large and one small. The length of the elastic band is very effective to save unnecessary waste of the elastic band.

Efficiency

- There are two splicing methods of overlapping and flat splicing, the whole process is automatic operation, automatic feeding, automatic cutting, automatic splicing, automatic receiving-completein one time. -A person can operate 5 machines at the same time. The number of rubber bands processed by each equipment is 5500 pieces/10H

- F161 series: the range of the elastic band is 110mm-999mm after overlapping, Width range 15*65mm

Application

- It is suitable for the splicing process of multiple specifications of elastic bands, and the stitches are smooth and beautiful.

Optional

- Rotary receiving device: Rotating working disc design, each receiving rod can receive about 100 pieces and 500 pieces each time.

- Elastic band ironing device: After the elastic band is ironed by the ironing device, it is smooth and beautiful, can prevent shrinkage, reduce waste, and improve production efficiency and sewing quality.

Technical Parameters

-

Model

Model differentiation

Highest sewing speed

Sewing range

Flnished elastic diameter scope

Needle model

Air pressure

Weight

Dimensions

Voltage

-

SP-F1610Aultrasonic2,800 rpm15×65mm110mm-999mmDp×170.5Mpa、1.8L/min270Kg1230×990×1300mm(L×W×H)Single phase220V

-

SP-F1611ACold cutter2,800 rpm15×65mm110mm-999mmDp×170.5Mpa、1.8L/min270Kg1230×990×1300mm(L×W×H)Single phase220V

-

SP-F1612AUltrasonic, point2,800 rpm15×65mm110mm-999mmDp×170.5Mpa、1.8L/min270Kg1230×990×1300mm(L×W×H)Single phase220V

-

SP-F1613ACold cutter, point2,800 rpm15×65mm110mm-999mmDp×170.5Mpa、1.8L/min270Kg1230×990×1300mm(L×W×H)Single phase220V

-

SP-F1614AUltrasonic, visual2,800 rpm15×65mm110mm-999mmDp×170.5Mpa、1.8L/min270Kg1230×990×1300mm(L×W×H)Single phase220V

-

SP-F1615ACold cutter, vision2,800 rpm15×65mm110mm-999mmDp×170.5Mpa、1.8L/min270Kg1230×990×1300mm(L×W×H)Single phase220V

Download