Product Introduction

SP-4530BS

Electronic Pattern Sewing Machine

- SP-4530BS-H/M/X

- Video1

- Video2

Characters

- Electronic tension device

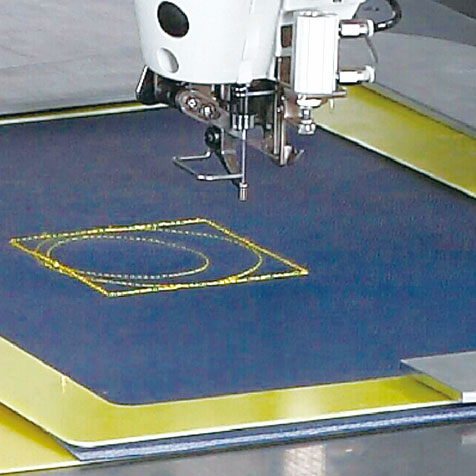

- Large sewing area

- Accurate and stable stitches

- Three-position rotary table (optional)

- Automatic pattern changing via bar code scanner (optional)

- Upper thread clamping device

Using servo motor system

The servo motor system improves the accuracy by five times from 0.05mm to 0.01mm,the highest accuracy in the industry,compared with traditional stepping motor feeding mechanism.Besides,it also reduces noise by 10db,feeds faster,improves the stitching trace in contrast with traditional system.

Accurate and stable stitches

Using high-precision servo control feed mechanism, with positioning compensation software control system, high-speed sewing / thick material sewing still able to achieve accurate and stable sewing tracks, effectively improve the the problem that traditional model will appear like deviation, moves on.

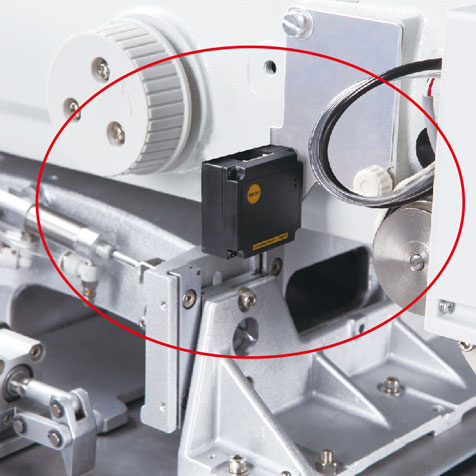

Electric tension device

With Variable tension of multi segments ,electric tension device leaves less margin and provides better stitching trace.

Upper thread clamping device

Effectively prevent the problem of unraveled lines at the beginning of sewing ,which avoids nest-like phenomenon.

Program changing device - Automatic Scanner(Optional)

Free of manual labor,this device changes programs automatically by auto-scanning ,which effectively saves labor and time compared with traditional manual operation.It can also prevent the problem of operating mistakes that influences daily operating.

Three-position rotary table (optional)

- For varieties of small quantity

- Sewing and clamping simultaneously, eliminate personnel / machine waiting time waste and improve efficiency

- Automatic positioning , automatic scanning and starting

- Automatically change programs in succession.

- Can sew different kinds of combined patterns in same material on one machine,which reduces the period of production

Technical Parameters

-

Model

Line

Highest sewing speed

Sewing area

Cloth feeding device

Stitch Length

Maximum stitch amount

Presser foot drive method

Press foot height

2- step presser foot

Rising amount of intermittent foot presser

Stroke by intermittent presser foot

Hook

Thread Wiper

Cutting device

Yarn trapper

Motor

Power

Air pressure

Machine size

Packing size

Weight

-

SP-4530BS-H/M/XSing-needle flat seam2,800 rpmMax.450×300 mmServo motor drive mode0.05 - 12.7mm20,000 needles/1 patternPneumaticMax. 30mmAll-in-one presser foot22 mm0 or 2-10mm(Factory defaults:3mm)Two times of shuttle hooks(Standard shuttle hooks are optional components)Standard facilityStandard facilityVariable electronic yarn trapperAC servomotor 550WSingle phase 100~120V, 200~240V,3-phase 200~240V,380~415V,350V0.5 Mpa 1.8 L/min1200×1100×14001300×1200×1500300Kg

Download