Product Introduction

SP-X109

Automatic Lace Loop Machine

- SP-X109

- SP-X109-ZD

Advantages

- Automatic feeding, cutting, folding, and sewing are completed at one time, and the entire process is automated, and the operator has no skill requirements.

- The length of the shoe loop and the half-fold can be easily set through the operation screen.

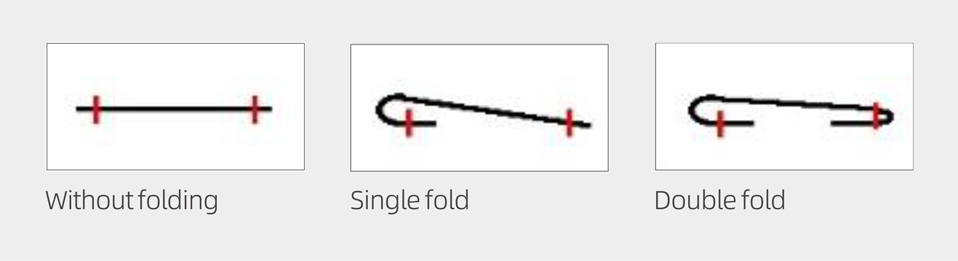

- Non-folding, single-folding, and one positive and one reverse tongue can be switched according to requirements.

- The two gripping methods can be switched according to different materials, and the applicability is wider.

- The cold cutting and eager cutting modes can be switched flexibly.

- It is suitable for different loop materials on the market.

- The lace loop device can be removed as a whole when not in use. It can be used as a pattern machine with multiple functions.

Efficiency

- SP-X109-ZD Operator: one person can operate multi machines, cycle sewing time 7.8 seconds/shoe tongue.

- SP-X109 Operator: 1 person, 1 machine, cycle sewing time 9 seconds/shoe tongue.

Application

Suitable for shoe tongue and ear piercing holes

Technical Parameters

-

Model

Highest sewing speed

Maximun sewing speed

Webbing width

Feeding method

Air pressure

Weight

Dimensions

Voltage

-

SP-X1092,700 rpm180x200x300mm( 100 pieces of 3mm thick tongues)6~16mmBy manual0.5 Mpa230Kg1200×900×1500mm(L×W×H)200~240V

-

SP-X109-ZD2,700 rpm180x200x300mm( 100 pieces of 3mm thick tongues)6~16mmAuto0.5 Mpa280kg1500×900×1500mm(L×W×H)200~240V

Download