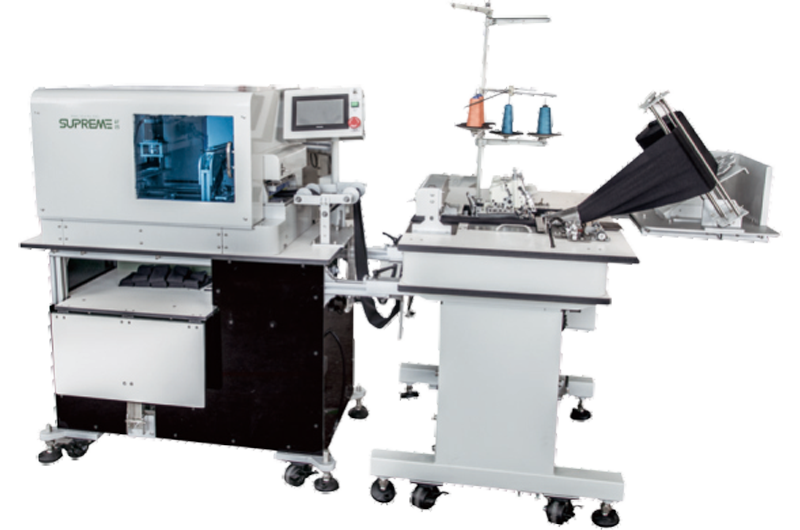

Easy to Operate & Master:

No professional skills required. Integrates multiple garment processing procedures,

with parameters directly set on the operation panel, lowering the operational

threshold.

High-Precision Automated Operation:

Precise control of cutting length and width. Full-process automation includes

sewing, cutting, feeding, turning and material collecting, ensuring high efficiency and stability.

Intelligent Design for Consumption Reduction:

Equipped with bobbin thread counting, automatic shutdown and alarm for upper thread breakage, and leftover material recycling functions. The material stacking mode can be flexibly adjusted to reduce material waste from the source.

Convenient & Efficient Specifification Switching:

Cuff and leg hem specififications can be quickly adjusted via a knob, adapting to

the production needs of multiple product categories.

Easy Troubleshooting:

The operation panel comes with a complete fault display function, facilitating

quick problem location and maintenance.

Space & Labor Saving:

Compact footprint, supporting one operator to manage multiple machines,

effectively reducing labor and site costs.